Nordamark Start

Our business idea is to offer a comprehensive growing system for microgreens, along with related consumables, to simplify and increase profitability of producing and selling microgreens.

The journey began with our founder growing microgreens on a kitchen table, gradually scaling production from just a few trays to hundreds per week, supplying multiple distributors across Sweden.

The growing system

The microgreen system was developed to address the numerous challenges we faced during the scaling of production. We discovered that the standard soil and tray method was not effective at larger scales, with watering proving to be the most problematic aspect.

Watering - How it solves problems

Channels were designed to enhance oxygen delivery to the roots, addressing the common risk of overwatering in the soil and tray system, where stagnant water could create an anaerobic environment lacking free oxygen. Such conditions often escalate problems quickly.

By employing a hydroponic watering method known as NFT (nutrient flow technique) with an intermittent schedule (1-2 minutes on, 3-4 times daily), water flows beneath the hemp fiber in the channel and into its grooves, promoting healthy root growth as the roots extend downward.

Deliver on the channel

The result was that the channel could also be utilized to deliver living samples directly to customers without the need for repackaging. This approach saves both time and costs while providing customers with a product that stays fresh and lasts longer.

Using Cartons

If deliveries couldn’t be made using the channel, the microgreens could easily be transferred directly into carton boxes using precut hemp fiber. This method also saves time and money by eliminating the need for cutting and harvesting. Interestingly, chefs perceived greater value in receiving living samples compared to cut microgreens in plastic containers, even when the contents were identical.

Microgreen seeds

Another important factor in growing microgreens is the seeds themselves. This is something we learned the hard way in our own production, and using seeds with a high germination rate and vigor is crucial to any operation. We test all our seeds regularly and keep track of all our seed lots and germination rates according to ISTA testing.

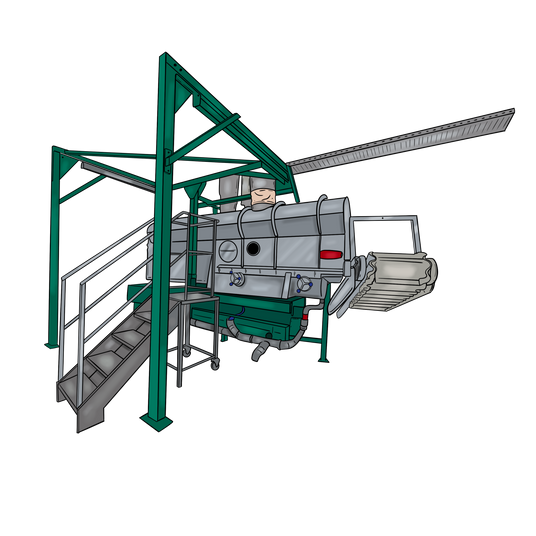

Seed hygienisation

Our current largest project is working on a machine that can clean/sanitize seeds from all mold, fungus, and insect problems. Even with rigorous testing today, you can't guarantee that the seeds won't have a problem, which specifically is an issue for larger seeds.

Using steam at a specific temperature and length ensures spores and seed diseases will be killed off. After the treatment, the seeds are dried and repackaged, ensuring high quality at a good price, which is something we strive for. The project is aimed to be finished by summer 2025.

Founder

Michael Skaret - Founder of Nordamark, has been working with microgreens for over 10 years.

Something that keeps me going is seeing other growers succeed. It's something special when you see a grower start with a small kit, but after a few years, they have grown into a commercial operation with employees. Growing microgreens allows you to start on the side and grow at your own pace.

If you are in need of some advice or want to know how to start, don't hesitate to contact me! (free of charge, of course!)